The time factor usually plays a decisive role in the product development. An experienced team is extremely important for fast processing. Our prototype construction experts work closely with the product development and manufacturing department.

We generate your prototype under defined conditions according to DIN EN ISO 13485 and, if desired, we can also manufacture under clean room conditions.

Our services

- Serial introduction according to DIN EN ISO 13485

- Serial production according to DIN EN ISO 13485

- Final assembly according to DIN EN ISO 13485

- Quality testing according to DIN EN ISO 13485

A prototype represents a functional and simplified test model of a planned product for defined purposes. It can only represent the final product either optically or technically.

A prototype also serves as preparation for a series production (first sample). It can also be planned as an individual item that is only intended to illustrate a specific concept or technology.

You can use the prototype to test the suitability or acceptance of your product. Accordingly, the prototype is also an essential development step in the design process.

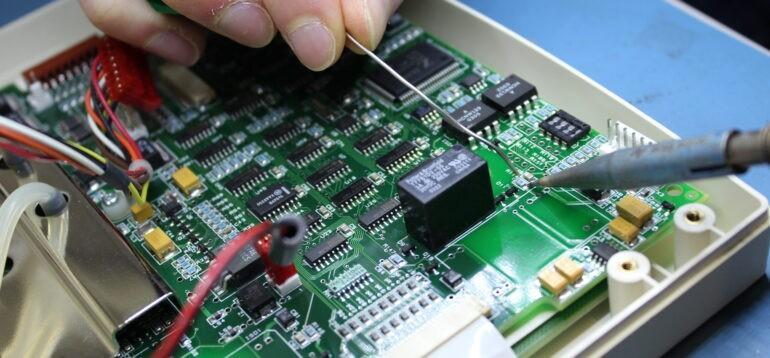

Enclosures are realized by rapid prototyping e.g. with fused deposition modeling or machining with CNC machines. The advantage of rapid prototyping is the speed and flexibility. Design changes can be implemented quickly with rapid prototyping. Manual post-processing ensures highest quality. We can efficiently produce the electronics using reflow technology. For the production as an implant, miniaturized electronics can be housed waterproof in biocompatible materials.

Types in our prototype construction

A demonstrator is a simple first setup to demonstrate a technology. We usually connect the necessary components on a plastic or wooden plate. Thus, we enable a fast and inexpensive assembly, which allows you to evaluate new technologies.

You need a possibility to show your skills and know-how at a exhibition?

You would like to present the conceived design for a new product at a exhibition or to a customer?

We can produce demonstrators for you for these purposes. These can be similar in appearance and haptics to the planned product or series part. Usually the function is put in the background or even omitted entirely.

When constructing a functional prototype, it often becomes apparent that theory and practice do not always match. For this reason, an iterative process must be run through optimization loops to bring a product up to the requirements. Functional prototypes can be used to verify the function of the planned product. Functional prototypes are often not similar in appearance to a serial part. Integrated control electronics can be larger in the function prototype because miniaturization has not yet progressed far. This is less important for a laboratory device. However, this is an important milestone in the development of point-of-care-diagnostics or mobile medical technology in general. In detail, this depends on the respective product. A functional prototype can be used to check the correct functioning of electronics, software, firmware and mechanical elements. We also manufacture functional prototypes of assemblies and housings.

A design prototype is designed to reproduce the external characteristics of the product being developed. A design prototype of devices is usually created without software and electronic components. It is used for presentation at exhibitions or to investors. In the case of point-of-care diagnostics, this can be a strategic intermediate step because of the required miniaturization of the electronics.

The technical prototype is very similar to the product being developed. Size, design and function correspond to the serial part with minor restrictions. This prototype can be used for usability studies, clinical trials and market surveys. In the case of laboratory diagnostics and laboratory equipment this is possible at an early stage.

The first sample is produced in the course of the serial introduction following the product development. An first sample corresponds in all aspects to the characteristics of a finished product. The first sample is used to check the quality of the production process.